Written by J.A Dobado | Last Updated on April 22, 2024

What is centrifugal filtration?

Centrifugal filtration is a method of separating solid particles from a liquid or gas using a high-speed centrifuge. It is a fast and efficient method that is widely used in a variety of applications, including laboratory and industrial settings.

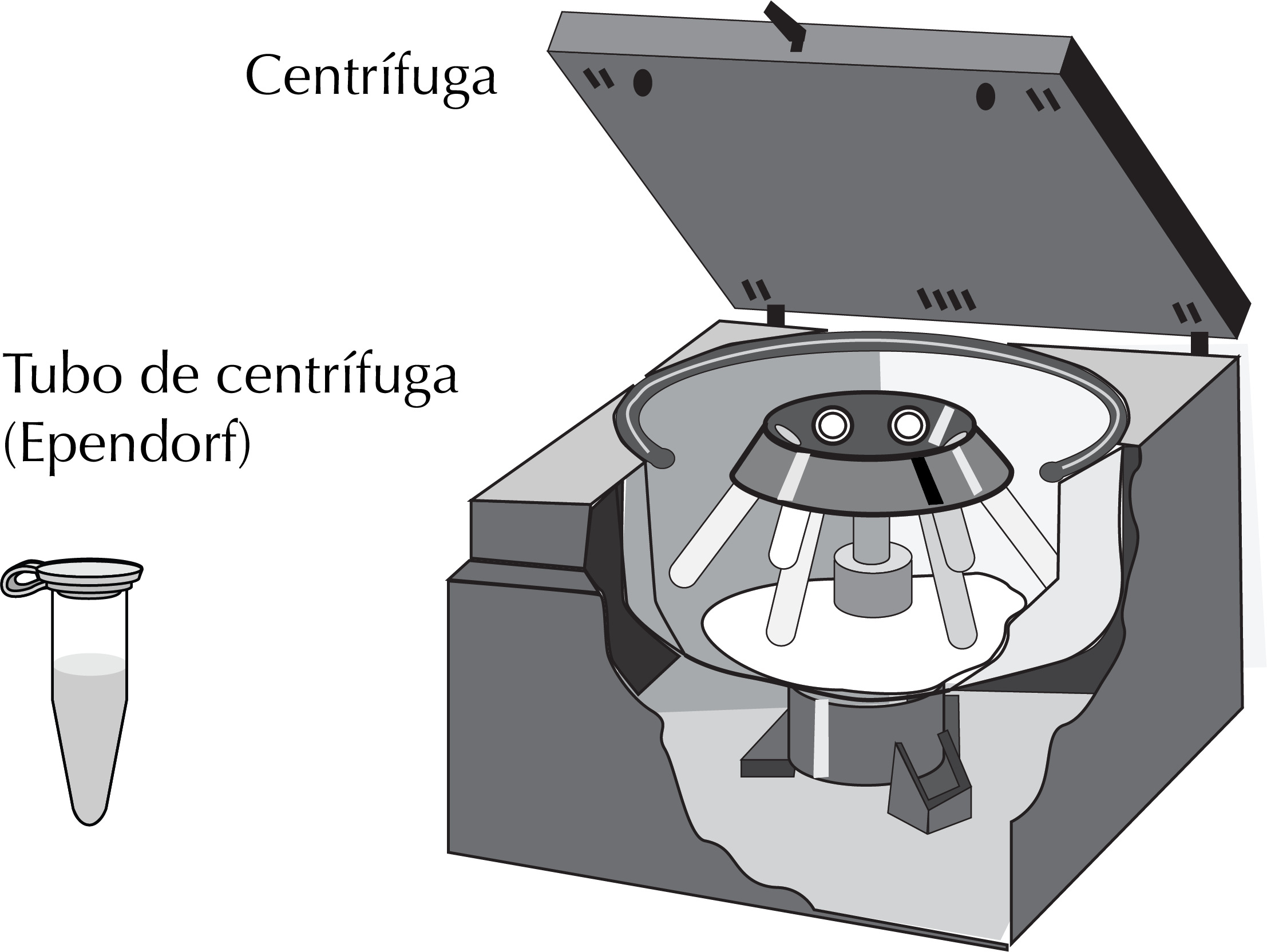

In centrifugal filtration, the sample is placed in a centrifuge tube, which is then loaded into a centrifuge rotor. The centrifuge machine spins the rotor at a high speed, causing the solid particles to settle to the bottom of the tube and the liquid to rise to the top. The liquid can then be poured off, leaving the solid particles behind.

Centrifugal filtration is a fast and efficient method that is widely used in a variety of applications, including laboratory and industrial settings. It is particularly useful for separating large volumes of liquid or suspensions with high solid content, and for separating particles that are too small or too delicate to be separated by other methods.

However, it requires specialized equipment and may not be suitable for separating very fine particles or for separating delicate or fragile compounds. It is also important to follow proper safety protocols when using a centrifuge machine, as the high-speed centrifugation can generate significant amounts of heat and pressure.

Step by Step centrifugal filtration

Centrifugal filtration is a method of separating solid particles from a liquid using a high-speed centrifuge. Here are the steps for performing a centrifugal filtration in the laboratory:

- Gather the necessary materials: You will need a centrifuge machine, a centrifuge rotor, and centrifuge tubes. You will also need the sample to be filtered and a container to collect the filtrate.

- Prepare the sample: Make sure the sample is properly prepared and in a suitable form for centrifugation. This may involve mixing, diluting, or adjusting the pH of the sample.

- Load the centrifuge tubes: Carefully transfer the sample to the centrifuge tubes, being careful to avoid spilling or splashing. Make sure the tubes are properly sealed and secure in the centrifuge rotor.

- Spin the centrifuge rotor: Load the centrifuge rotor into the centrifuge machine and set the appropriate speed and time for the centrifugation. Start the machine and allow the rotor to spin for the specified time.

- Collect the filtrate: Once the centrifugation is complete, carefully remove the centrifuge tubes from the rotor and pour off the liquid, which is called the filtrate.

- Discard the solid particles: Carefully remove the solid particles from the bottom of the centrifuge tubes and discard them.

- Clean and dry the equipment: Once you have finished the filtration, be sure to clean and dry the centrifuge tubes and rotor. Store the equipment in a clean and dry place for future use.

Pros and cons of centrifugal filtration

One advantage of centrifugal filtration is that it can be used to separate large volumes of liquid or suspensions with high solid content. It is also effective at separating particles that are too small or too delicate to be separated by other methods, such as gravity filtration or vacuum filtration.

However, there are some limitations to centrifugal filtration. It requires specialized equipment, such as a centrifuge machine and centrifuge tubes, which can be expensive and time-consuming to set up and operate. It is also not suitable for separating very fine particles or for separating delicate or fragile compounds, as the high-speed centrifugation can cause damage or degradation.

In addition, centrifugal filtration has some inherent safety risks. The high-speed centrifugation can generate significant amounts of heat and pressure, which can lead to the generation of flammable or explosive gases. It is important to follow proper safety protocols when using a centrifuge machine, including wearing protective equipment, following the manufacturer’s instructions, and maintaining the equipment in good working order.

Summary

Centrifugal filtration is a useful and effective method for separating solid particles from a liquid or gas. It is widely used in a variety of applications, including laboratory and industrial settings, and has many advantages over other methods of filtration. However, it is important to be aware of its limitations and to follow proper safety protocols when using a centrifuge machine.

References

- Isac-García, J.; Dobado, J. A.; Calvo-Flores, F. G.; and Martínez-García, H. (2015). Experimental Organic Chemistry Laboratory Manual. Elsevier Science & Technology. ISBN: 978-0-12-803893-2