Written by J.A Dobado | Last Updated on April 22, 2024

For proper maintenance of laboratory equipment, it should be cleaned and dried after each experiment so that dirt does not interfere with the performance of each new experiment. Otherwise, inconveniences may arise, such as the presence of colored substances in the equipment used, which may alter the final appearance of the product.

Also, there may be a decrease in the yield of the products obtained due to total or partial destruction of the reagents. Worse still, the uncontrolled formation of irritating or toxic substances, due to the chemical incompatibility of the reagents with these impurities. This last point is the most serious in terms of safety. The waste that can foul/contaminate laboratory material is of a very diverse nature and may belong to one of the following groups:

- Inorganic salts.

- Salts with some ion of organic nature (for example, quaternary ammonium salts).

- Grease from hands or from adjustments and ground glass joints.

- Organic substances of higher or lower viscosity.

- Organic solids.

- Polymeric and resinous substances, usually brownish or dark in color, obtained as decomposition by-products in many reactions.

Conventional cleaning procedures

Washing procedures vary according to the nature of the residue, the degree of adhesion and the intended use of the material. For a conventional reaction and with a mild to moderate degree of soiling we will follow the normal protocol for glassware:

- Dismantle all used equipment immediately after completion of a reaction to prevent it from getting stuck.

- Remove grease residues, if any, from seals and grindings with a piece of filter paper.

- Rinse with a small amount of solvent such as acetone or CH2Cl2Cl2 to remove organic matter, especially in the area of the ground joints.

| WARNING! “Organic waste and solvents used for washing the material must be disposed of in suitable containers (chlorinated / non-chlorinated) (acidic / basic), never pour them down the sink.” |

- Wash the material, preferably with a liquid soap (solid detergents usually leave more residues) with the help of a brush of suitable proportions, so that the soapy water reaches all the areas of the container.

- Rinse with plenty of running water.

- Rinse with deionized water, since tap water contains dissolved salts that will leave residues when drying.

For volumetric instruments such as pipettes, burettes, test tubes or volumetric flasks that have been used for the measurement of solvents, reagents or solutions, a wash with a compatible solvent followed by a deionized water-water wash would be sufficient.

Throughout the entire process, minimum safety standards must be observed, such as protecting the eyes and hands with goggles and gloves when handling potentially hazardous waste and disposing of it in the corresponding containers.

Non-conventional cleaning procedures

In most cases the protocol described above will be sufficient, however, if normal washing is not effective, it is advisable to follow a procedure that will depend on the nature of the residue.

For most residues of inorganic origin, such as metallic salts, washing with dilute acid (HCl or H2SO4) will be adequate. If it is observed to persist, good results are obtained by increasing the acid concentration.

For persistent organic residues, alcohols (EtOH, MeOH), DMF or DMSO (see list of acronyms) can be used to wash the material, since they have a strong dissolving capacity, both at room temperature and if heated gently with the aid of an air dryer. In all cases, the possibility of the generation of harmful vapors from the solvent or the products to be treated must be taken into account.

Cleaning material

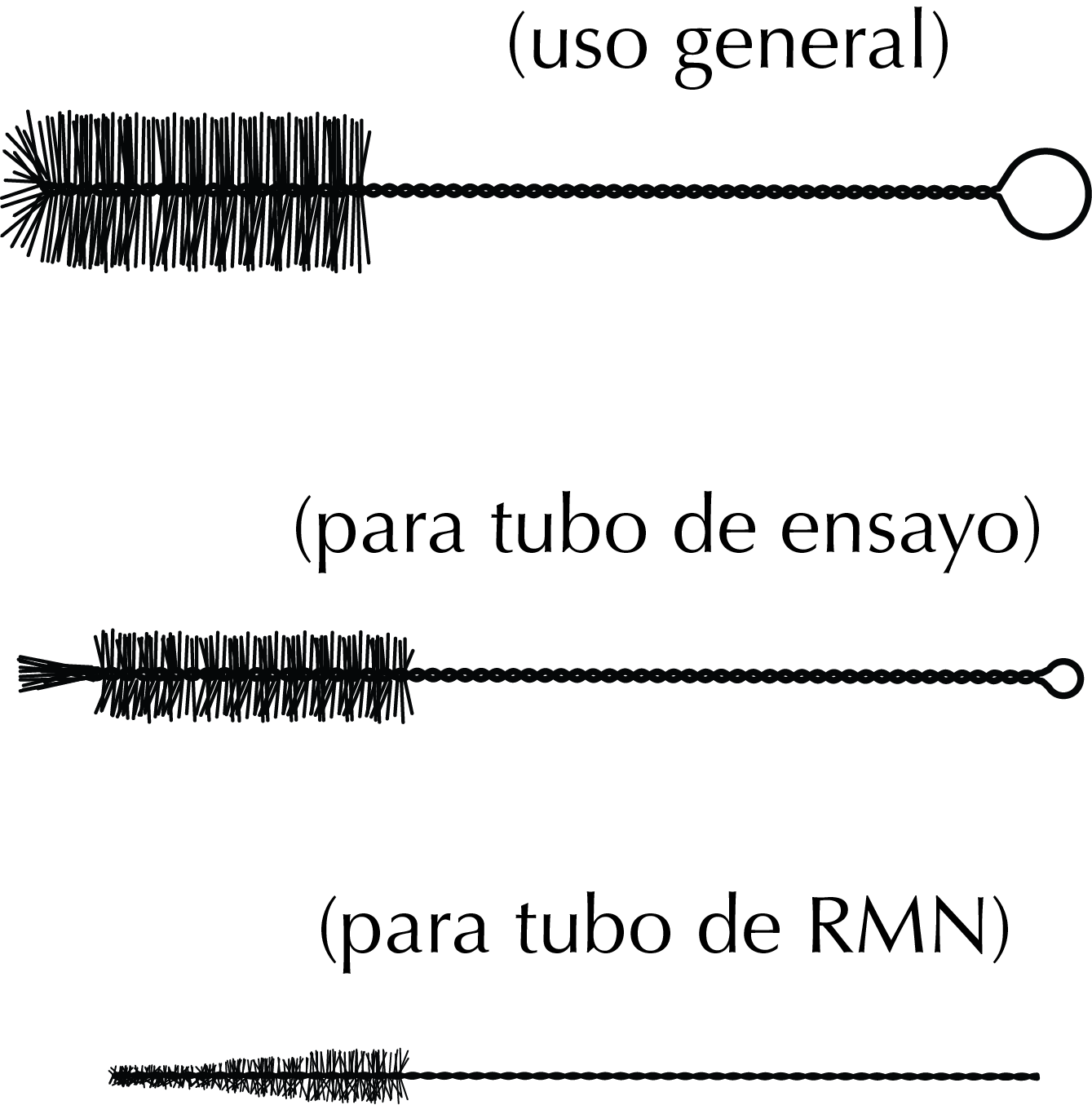

Glassware is cleaned in the sink using liquid detergent and cleaning brushes designed for this purpose (see Figure). In certain cases, ultrasonic baths are used to clean laboratory equipment, especially glassware. It proves to be an alternative to conventional cleaning methods. The application of ultrasound to all types of soiled material facilitates the removal of particles adhering to surfaces, even in areas that are difficult to access.

Aggressive cleaning procedures

Cleaning glassware is easy if it is done immediately after finishing an experiment. If we let time pass, the substances that were in contact with the glass walls may react with the glass or with oxygen in the air, so the more time passes, the more difficult it is to clean later. If you cannot “fresh” the glassware immediately it is advisable to let it soak in water to prevent dirt from “sticking” to the glass.

There are several soaps and detergents suitable for washing glassware and should be used in the first instance when cleaning dirty glassware.

When these detergents are ineffective, solvents such as acetone, toluene, etc. can be used. The use of organic solvents entails additional health risks when breathing the vapors or when they come into contact with skin or clothing.

One of the most commonly used solvents for cleaning is acetone, but it presents two problems: it is expensive and it is highly flammable, so extreme precautions should be taken not to use it if there is any source of ignition nearby, such as open flames or very hot surfaces.

Always try to use small amounts of acetone, usually less than 5 ml will suffice. Used acetone can be used effectively several times before discarding it. If acetone does not work, then another organic solvent can be tried by treating in the same way as described for acetone.

For soiling, dyes and residues that are not removed by persistent solvents, acids such as H2SO4 or HNO3 can be used. With great care, and wearing protective goggles, add about 20 drops of concentrated H2SO4 and about 5 drops of HNO3 in the bottle to be washed avoiding at all costs that they fall on the skin or clothes, if it falls on the skin it produces serious burns and on the clothes it produces holes.

Once the acids are inside the container, shake gently for a few minutes until the reaction with the contaminant has ceased. Heating in a warm water bath may speed up the cleaning process. Once cleaning is complete, discard the remaining acids in the appropriate container.

Whatever the effective cleaning method, solvents or acids, the glassware should be rinsed thoroughly with water and then washed with soap and water, following the protocol described above.

When the residues that remain adhered to the material are difficult to remove by conventional methods, either because of the nature of the substance or the type of material being handled, more aggressive procedures are required for proper cleaning.

Several procedures, which may be useful, are described below:

Solutions of concentrated bases in alcohols

If the residues to be removed are organic, the material can be washed in a solution of MeOH or EtOH saturated in NaOH or KOH. These solutions are very corrosive, they attack the skin so it is necessary to always work with gloves to avoid burns, besides they are potentially flammable so it is necessary to avoid the proximity of flames or heat sources. This procedure should not be used for long periods of time or if the residues present these characteristics:

- Material contaminated with metal-containing substances.

- Material contaminated with oxidizing agents.

- Material with parts made of sintered glass such as filter plates or some chromatography columns.

- Pipettes and other graduated or gauged material, which, although effective in eliminating grease, damage the marks that allow volumes to be measured, rendering them unusable.

Chromic acid mixture

It is perhaps one of the most popular methods for the removal of organic and inorganic residues on glass material when normal cleaning methods are not effective. For example, in the case of filter plates or other sintered glass material or in the removal of polymeric and resinous substances difficult to clean by other methods, it proves to be a very effective procedure. A serious drawback is that Cr(VI) is highly toxic due to its carcinogenic nature and its strong environmental impact. Its use has been banned in some laboratories.

The chromic mixture is prepared using the following proportions: 6.5 g of potassium dichromate K2Cr2O7, 10 ml of water and 100 ml of concentrated H2SO4.

The chromic mixture can be replaced by solutions of ammonium peroxodisulfate (NH4)2S2O8, which has a similar efficacy due to its oxidizing character and is less dangerous.

Aqua regia

Aqua regia is a reagent consisting of 1 part concentrated HNO3 and 3 parts concentrated HCl (it is recommended to add one part of water when storing to minimize the formation of chlorine vapors). It has an extraordinary oxidizing character, to the point that it is the only solution capable of dissolving gold Auº.

Because of this property, it must be used with great care due to its pronounced corrosive character. In addition, when it acts it is reduced, generating chlorine Cl2 and nitrogen oxides vapors, both of which are highly toxic. This method should only be used when conventional cleaning methods fail.

Potassium permanganate

A solution of 10 g of potassium permanganate KMnO4 per liter of water is usually used. It can be alkalinized before use with sodium carbonate Na2CO3. After use, brown stains on glass can be removed with concentrated HCl.

| DANGER! “Aggressive cleaning methods must be carried out always in fume cupboard, as toxic or malodorous gases may be produced due to thedecomposition of organic matter or the oxidizing agent used.” |

Drying glassware

The glass material must be dry both for further use and for storage. Some material can be air-dried by simply placing it in a colander, however, the most efficient procedure is to use a drying stove.

The oven temperature can be adjusted to around 75 °C to ensure that everything is perfectly dry. This process is important, as many reactions can be spoiled by the presence of water or other solvents.

| Practical tips: “If dry glassware is needed in a short period of time, acetone can be used (Acetone left over from washing should be disposed of in the appropriate waste container.) to wash away water residues before introducing them into the oven. This procedure is especially recommended for materials such as reflux coolants, adapters and various materials with curved areas that tend to retain water droplets.“ |

Plastic, silicone, rubber or Teflon material should never be introduced into the drying oven, nor material with traces of grease or material that is not perfectly clean, since the heat carbonizes them and it is much more difficult to remove them.

Drying volumetric material

As for the drying of volumetric material such as pipettes, burettes, test tubes or volumetric flasks used for the measurement of solvents, reagents or solutions (volumetric material), it must be done with a current of hot air (for example, air dryer) or in the air, since if it is introduced in the oven the dilatations produced by the heat of the oven in the glass and the subsequent contractions when it cools alter the gauging and therefore, the accuracy is lost in subsequent measurements.

| DANGER! “When removing material from the stove use special gloves, crucible tongs or any other option that avoids burns on fingers and hands.“ |

Video on cleaning glassware

References

- Isac-García, J.; Dobado, J. A.; Calvo-Flores, F. G.; and Martínez-García, H. (2015). Experimental Organic Chemistry Laboratory Manual. Elsevier Science & Technology. ISBN: 978-0-12-803893-2