Written by J.A Dobado | Last Updated on April 22, 2024

What is gravity filtration?

It is used when we want to preserve, a liquid that we want to separate a solid (solid impurities from an organic liquid). The impurity can be a drying agent (Na2SO4), or an undesired by-product or a reactive solid is to be disposed of. The gravity filtration can be used to obtain solid products, although it is generally employed in the vacuum filtration for this purpose because it is faster. The procedure that is used is the so-called “gravity filtration in hot” to separate the impurities insoluble in a solution of hot.

Hot filtrations require a flutted filter paper and a careful attention to the procedure to keep the solution hot, but with care so that the solvent does not evaporate. If we use non-water solvents (organic solvents), you must attach a refrigerant of reflux which prevents from evaporation, and also whenever the solvent is flammabled to avoid accidents (see how to mount a reflux).

The equipment needed to perform this filtration is:

- Conical funnel.

- Ring clamps to attach the funnel.

- Erlenmeyer flask (or other container) to collect the liquid after filtration.

- Fluted filter paper

The solid (disposable) is retained on the filter paper set in the conical funnel, through which the solution is recovered.

Pros and cons of gravity filtration

Here are some pros and cons of gravity filtration:

Pros of gravity filtration:

- Simple and easy to perform.

- Does not require any specialized equipment or power source.

- Can be used in a wide range of applications, including laboratory and industrial settings.

Cons of gravity filtration:

- Relatively slow compared to other filtration methods.

- May not be suitable for separating very fine particles or for filtering large volumes of liquid.

- Can be prone to clogging or plugging, especially when filtering suspensions with high solid content.

Video about Gravity Filtration

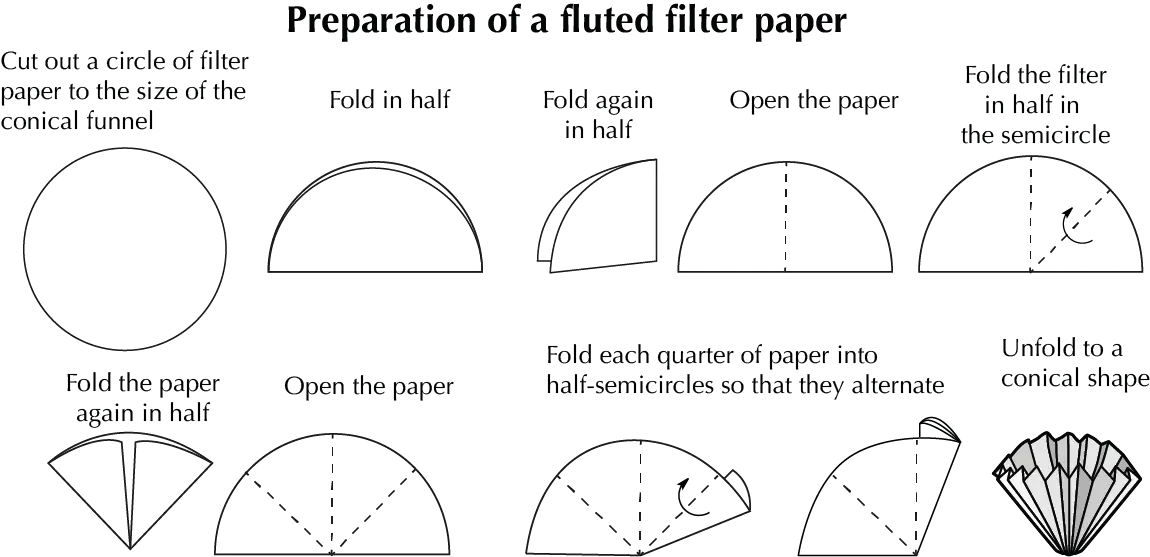

Preparation of the filter paper

The fluted filter paper is made from a square piece of filter paper by cutting it to form a circle. Then, the paper is folded as shown in the Figure.

The purpose of the folds is to facilitate the passage of the liquid through the paper to increase the effective area of filtering. The size of the filter should not protrude above the rim of the conical funnel.

Filtration process

- The iron ring is fixed to the rack and placed the funnel conical.

- The height of the iron ring is regulated so that the output of the funnel into the collection container (Erlenmeyer flask or beaker).

- Once prepared, the filter pleats are placed in the funnel, conical.

- The liquid is poured into the filter without allowing it to overflow. This can be done using a bar of police (see Figure).

- Let the liquid falls by gravity on the receptacle.

- Finally, you add a small amount of solvent to wash the solid remaining

in the filter.